Delivery time: 60~75 days (approx.)

Payment term: T/T with 30% down payment

Warranty period: 14 months after delivery

Like it ? Share it:

- Technical Specs

- Product Details

- Standard Equipment

- Optional Equipment

- Purchase history

- Customer Reviews

- Buyers Q & A

Saddle Moving Type Surface Grinder![]()

Model: FSM 2050AHD

X-axis travel: 560mm

Y-axis travel: 240mm

Table size: 200x508mm

Wheel size: 200x20x31.75mm

| Model | FSM 2050AHD |

| Table dimensions | 200 x 500 mm |

| T-slot quantity / width | 1 / 14 mm |

| Electric magnet clamping plate | 200 x 460 mm |

| Max. travel, longitudinal | 560 mm |

| Max. travel, cross | 240 mm |

| Max. distance spindle / table | 450 mm |

| Max. workpiece weight* | 180 kg |

| Grinding wheel | 200 x 20 x 31,75 mm |

| Table speed, hydraulic | 7 - 25 m/min |

| Cross adjustment | |

| Automatic adjustment, cross | 0,5 - 8 mm / Stroke |

| Rapid feed, cross | 990 mm/min |

| Adjustment per handwheel rotation | 4 mm/rev. |

| Scale division on handwheel | 0,02 mm |

| Vertical adjustment | |

| Automatic adjustment, vertical | 0,005 / 0,01 / 0,02 / 0,03 / 0,04 / 0,05 mm |

| Rapid feed, vertical | 480 mm/min |

| Adjustment per handhwheel rotation | 2 mm/rev. |

| Scale division on handwheel | 0,005 mm |

| Motor power of sanding spindle | 2,2 kW |

| Spindle speed | 2850 rpm |

| Motor power of hydraulic pump | 0,75 kW |

| Motor power of vertical feed | 0,5 kW |

| Length | 2160 mm |

| Depth | 1650 mm |

| Height | 1840 mm |

| Weight approx. | 1640 kg |

Including Siemens PLC-control for programming simple sanding cycles via touchscreen

State of the art hydraulic system guarantees soft table traverse even at high work load

Seperate hydraulic unit with heat exchanger to omit vibrations and thermal load

Solidly constructed and well supported structure assures high stability

Plastic-coated counter guide in x- and y-axis assure a low slip-stick-effect

Infeed via rapid feed to height of workpiece, adjustable to finishing and sparking, automatic lift at program end

Spindle features axial and radial, clearance-free, pre-tensioned bearings

Digitally controlled, automatic vertical feed with servo motor

Adjustable longitudinal and cross table movement via end stops

V-flat longitudinal table guide, double-V cross table guide

Siemens SMART-panel with touchscreen

Electronic handwheel

Magnetic clamping plate

Grinding wheel

Wheel flange

LED working light

Wheel extracting unit

Balancing arbor

Dressing diamond

Coolant device

Central lubrication

Protective covers

Demagnetization device

Operation manual

Extra grinding wheel

Extra wheel flange

2-axis digital readout

Wheel balancing base

Worktable protective cover

Overhead parallel dresser

Cooling system with magnetic separator

Cooling system with Paper filter

Cooling system with Magnetic separator & Paper filter

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

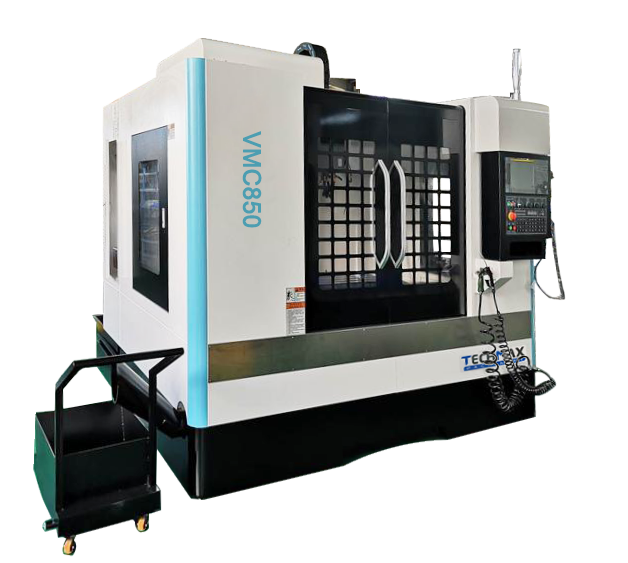

Overview Grinding, Surface Grinding, Manual Surface Grinding Machine, FSG AHD Series - Automatic Precision Surface Grinding Machine (3-Axes Automatic),FSG AHR Series - Semi-Auto Precision Surface Grinding Machine (2-Axes Automatic),Cylindrical Grinding, OD Cylindrical grinding machine,Universal OD-ID cylindrical grinder, Crankshaft grinder, Centerless Grinding,Centerhole Grinding - Centre Grinding Machines,Centerhole grinding machine - Centre grinder,Centerhole CNC Grinding Machine - CNC Centre grinder,Tool grinding and Form Grinding,Five-Axis CNC tool grinder,Turn,Overview Turning,Mill,Overview Milling Machines - Machining Centers,Vertical Machining Centers - VMC Series Premium Line,High Speed Vertical Machining Centers,High Speed Graphite Milling Machining Centers,Gantry type Vertical Machining centers,Conventional Milling Machines,Drill, overview, CNC Plate drilling machine,CNC Drilling lines,optional equipment for our cnc Drilling lines, deep hole drilling machines,Hone,Overview Honing Machines,Horizontal precision Digital Honing Machines,Deep Hole Honing Machine,Vertical Deep Hole Honing Machine,Deep hole,Overview Deep hole machining,Single coordinate single spindle CNC Gundrilling Machines,Single coordinate multi spindle CNC Gun drilling Machines,Three coordinate single spindle deep hole driling machine,Deep Hole Drilling and Boring Machine - BTA Boring and drilling machines, Big diameter Boring machine - Big diameter BTA machine,Skiving & Roller Burnishing Machines,Deep Hole Honing Machine,Deep hole drilling Technology,Deep hole drilling accesoiries,Tube Bar,Overview Tube Bar Machines,Semi automatic 2D NC tube bending machines,Automatic Servo driven Single layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines + Roll bending,Automatic Servo driven clockwise and counterclockwise CNC Tube Bending Machines,Automatic Servo driven Left and right head CNC Tube Bending Machines,Carbide Rod Cutter - carbide Blank cutter,Wire,Overview Wire Bending - Forming,Wire Forming Machines,Spiral Forming Machines,Wire Bending Machines,Plate Sheet,Overview Plate and sheet machinery

Tel: +86-(0)571-5690 6181

Fax: +86-(0)571-5690 6183

E-mail: info@techmax-machine.com

Add: No.702, Guali commercial center, Xiaoshan district, Hangzhou, Zhejiang, China.