Delivery time: 60~75 days (approx.)

Payment term: T/T with 30% down payment

Warranty period: 14 months after delivery

Like it ? Share it:

- Product Details

- Technical Specs

- Standard Equipment

- Optional Equipment

- Purchase history

- Customer Reviews

- Buyers Q & A

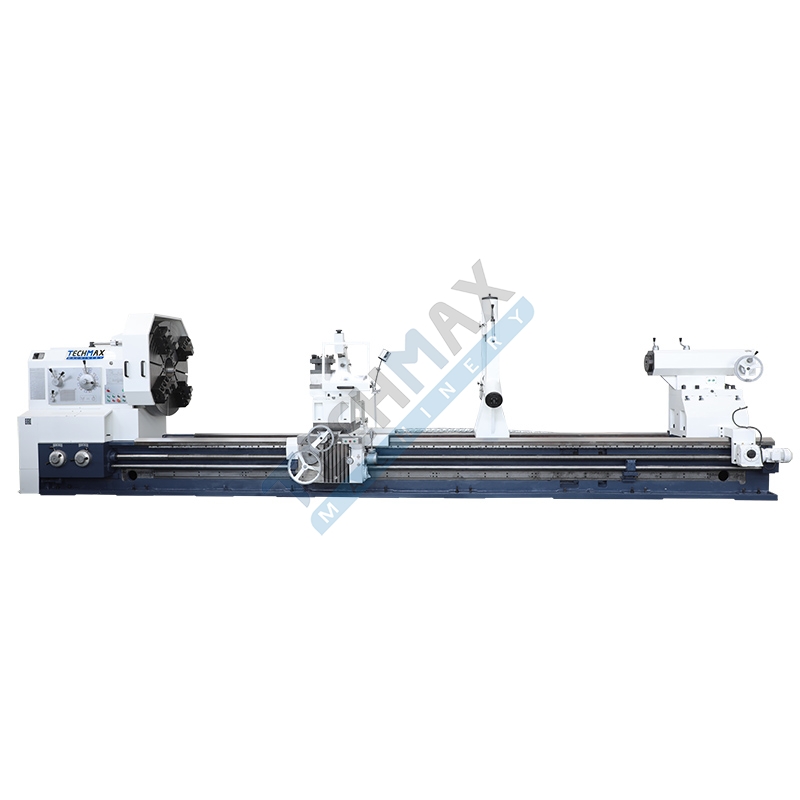

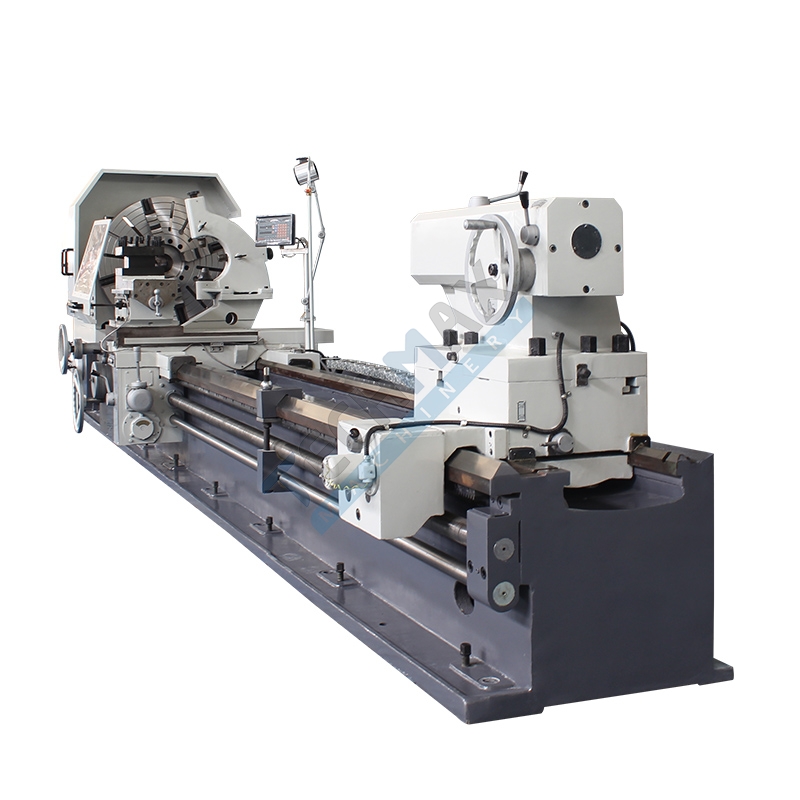

Heavy Duty Precision Lathe![]()

Model: SDM 1600C

Center distance: 3/4/5/6/8/10/12 m

Swing over bed: Φ1600 mm

Loading weight: 10000 kg

Bed width: 970 mm

Techmax SDM-series Lathe - Description Techmax SDM-series lathe is designed to provide outstanding performance and structural rigidity with large Φ130mm spindle bore for turning and cutting a large workpiece | |||

Single piece cast iron bed Heavily ribbed wide bed with induction hardened and precision ground bed ways for rigidity and low vibration. Its design authorizes chips fast removal. It is equipped with a bridge of which dismounting allows increase machining diameter.

|

| ||

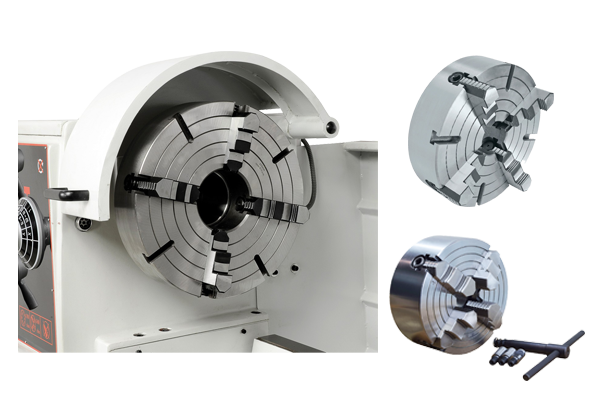

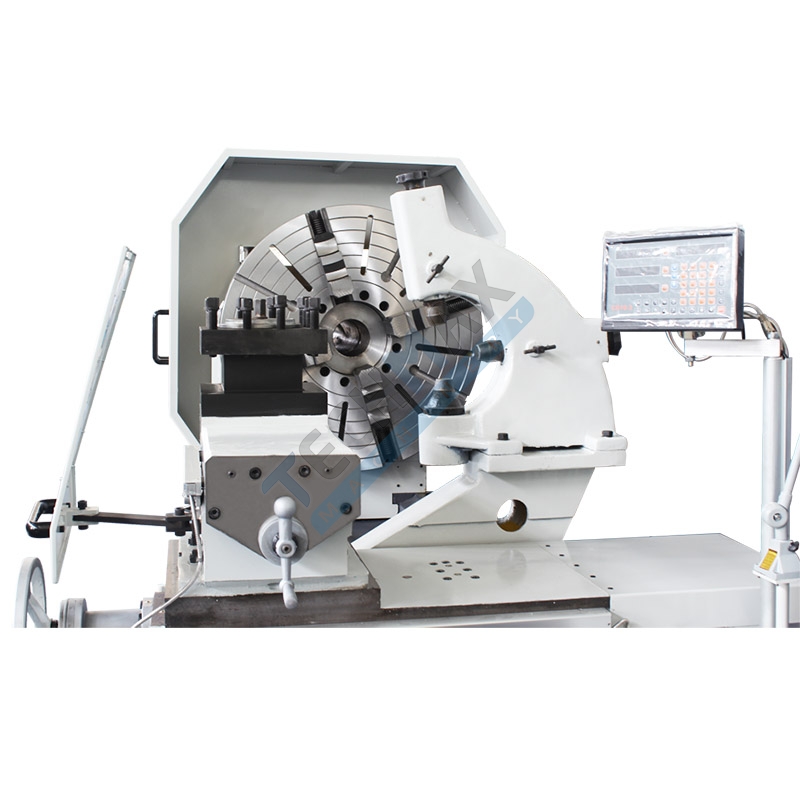

| Headstock The precision ground spindle is supported by high precision bearings suitable for both heavy and precision cutting. Spindle bore Φ105 mm is designed for large chucking capability.

| ||

Width of Bed: 970 mm The slides are of an extremely rigid construction and the backlashes are adjusted by means of tapered keys. The slides are endowed with rubber wipers avoiding the guideways gripping. The carriage, fixed on the longitudinal slide, provides automatic feeds, rapid feeds and working feeds, as well as, manual feeds in two directions(longitudinal and cross).

|

| ||

| Pivoting upper slide The cross slide runs in a dove-tail guideway. Adjustment via pressure plate. Feed automatic or with handwheel. Both the longitudinal and cross slides can be clamped. A feed lever with safety lock prevents longitudinal and axial feed switch-through.

| ||

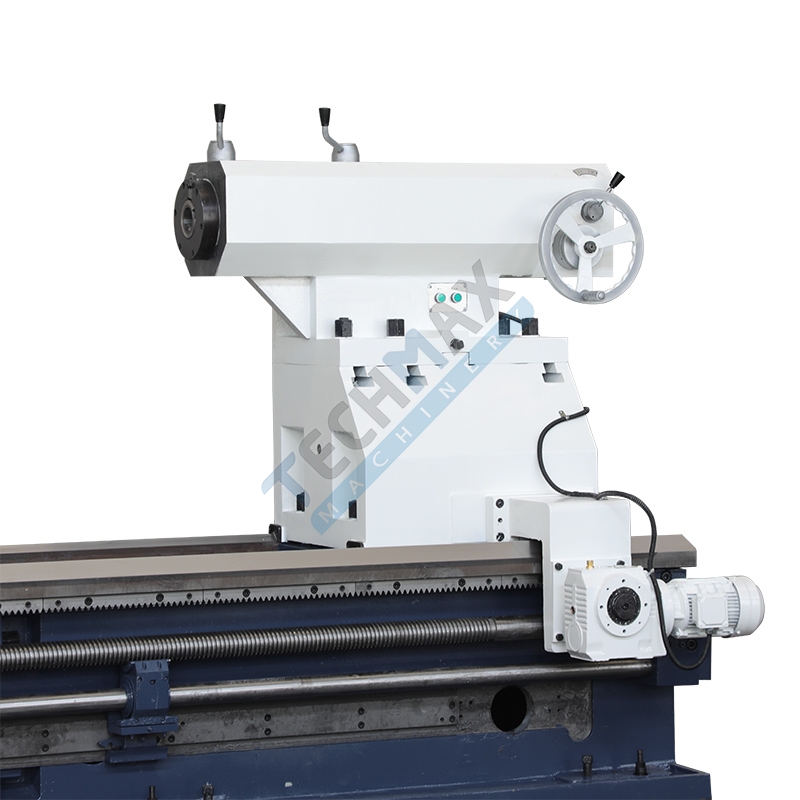

High Rigid Tailstock The tailstock, made of top quality, has a rigid construction, vibration absorbing and can easily travel along the bed guideways. A lead screw, driven by hand wheel, allows axial movement of the quill on a 250 mm maximum travel. It can be set eccentrically with max. ±13 mm for cutting.

|

| ||

| Steady rest standard The steady rest serves as a support for long shafts (length to diameter ratio of 3:1 or greater). The steady rest can be placed anywhere along the length of the workpiece.

| ||

Specification | Unit | SDM 1250C | SDM 1400C | SDM 1600C | SDM 1800C |

Distance between centers | mm | 3000/4000/5000/6000/8000/10000/12000 | |||

Center height | mm | 625 | 700 | 800 | 900 |

Swing over bed | mm | Φ1250 | Φ1400 | Φ1600 | Φ1800 |

Swing over cross slide | mm | Φ865 | Φ1010 | Φ1210 | Φ1410 |

Max. workpiece weight | kg | 10000 (opt: 12000) | 10000 (opt: 12000) | 10000 (opt: 12000) | 10000 (opt: 12000) |

Bed width | mm | 970 | 970 | 970 | 970 |

Max. cutting force | N | 45000 | 45000 | 45000 | 4500 |

Spindle nose fixture | - | A2-15 | A2-15 | A2-15 | A2-15 |

Spindle bore | mm | Φ130 | Φ130 | Φ130 | Φ130 |

Spindle taper | - | Metric 140 | Metric 140 | Metric 140 | Metric 140 |

Spindle speed | rpm | (21) 3.15-315 | |||

X/Z-axis feed kinds | kinds | 56 | 56 | 56 | 56 |

Feed range | mm/rev | Longitudinal: 0.1-12; Cross: 0.05-6; Top tool-post: 0.025-3 | |||

Metric thread | mm | (44) 1-120 | (44) 1-120 | (44) 1-120 | (44) 1-120 |

Inch thread | TPI | (31) 28-1/4 | (31) 28-1/4 | (31) 28-1/4 | (31) 28-1/4 |

Module thread | MP | (45) 0.5-60 | (45) 0.5-60 | (45) 0.5-60 | (45) 0.5-60 |

Diametrical thread | DP | (38) 1/2-56 | (38) 1/2-56 | (38) 1/2-56 | (38) 1/2-56 |

Cross slide travel | mm | 650 | 650 | 650 | 800 |

Top slide travel | mm | 300 | 300 | 300 | 300 |

Tool section size | mm | 45×45 | 45×45 | 45×45 | 45×45 |

Tool post swivel angle | ° | ±90° | ±90° | ±90° | ±90° |

Rapid feed speed | mm/min | Longitudinal: 3740; Cross: 1870; Top tool-post: 935 | |||

Tailstock sleeve diameter | mm | Φ220 | Φ220 | Φ220 | Φ220 |

Tailstock sleeve travel | mm | 300 | 300 | 300 | 300 |

Tailstock sleeve taper | - | MT6 | MT6 | MT6 | MT6 |

Main motor power | kw | 22 | 22 | 22 | 30 |

Machine length | mm | 6020/7020/8020/9020/11020/13020/15020 | |||

Machine width | mm | 1995 | 1995 | 1995 | 2665 |

Machine height | mm | 2175 | 2325 | 2525 | 2680 |

* Specifications subject to change without notice.

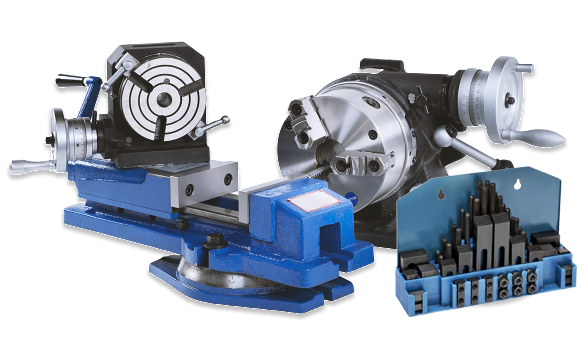

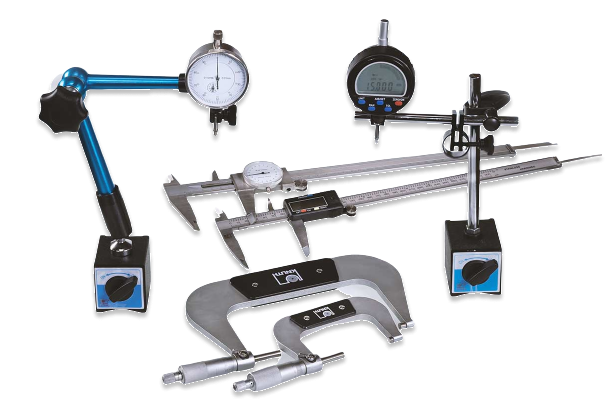

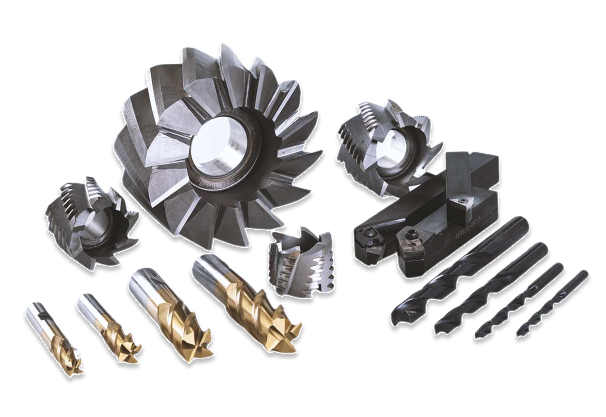

Techmax SDM-series Lathe - Standard Accessories | |

Complete with:

|

|

Techmax SDM-series Lathe - Optional Accessories | |

|

|

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

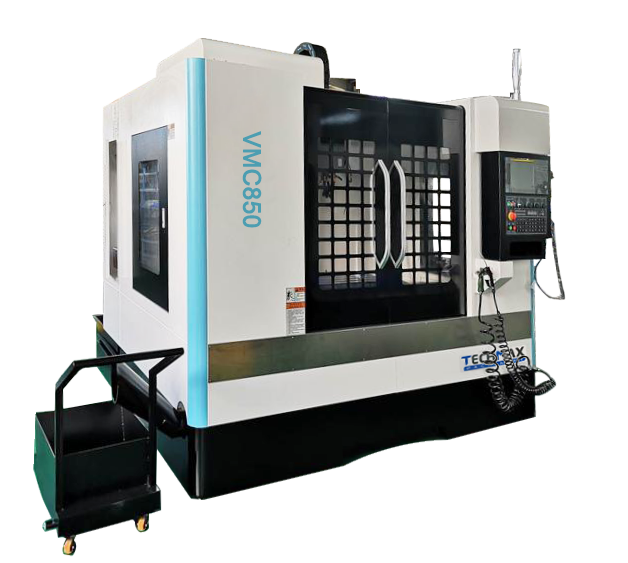

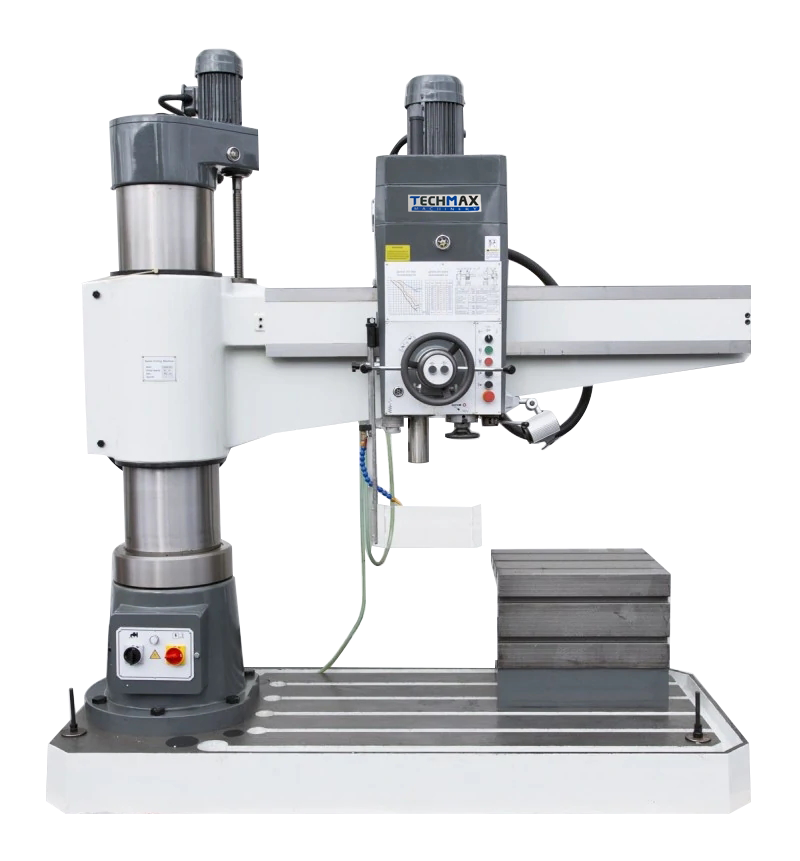

Overview Grinding, Surface Grinding, Manual Surface Grinding Machine, FSG AHD Series - Automatic Precision Surface Grinding Machine (3-Axes Automatic),FSG AHR Series - Semi-Auto Precision Surface Grinding Machine (2-Axes Automatic),Cylindrical Grinding, OD Cylindrical grinding machine,Universal OD-ID cylindrical grinder, Crankshaft grinder, Centerless Grinding,Centerhole Grinding - Centre Grinding Machines,Centerhole grinding machine - Centre grinder,Centerhole CNC Grinding Machine - CNC Centre grinder,Tool grinding and Form Grinding,Five-Axis CNC tool grinder,Turn,Overview Turning,Mill,Overview Milling Machines - Machining Centers,Vertical Machining Centers - VMC Series Premium Line,High Speed Vertical Machining Centers,High Speed Graphite Milling Machining Centers,Gantry type Vertical Machining centers,Conventional Milling Machines,Drill, overview, CNC Plate drilling machine,CNC Drilling lines,optional equipment for our cnc Drilling lines, deep hole drilling machines,Hone,Overview Honing Machines,Horizontal precision Digital Honing Machines,Deep Hole Honing Machine,Vertical Deep Hole Honing Machine,Deep hole,Overview Deep hole machining,Single coordinate single spindle CNC Gundrilling Machines,Single coordinate multi spindle CNC Gun drilling Machines,Three coordinate single spindle deep hole driling machine,Deep Hole Drilling and Boring Machine - BTA Boring and drilling machines, Big diameter Boring machine - Big diameter BTA machine,Skiving & Roller Burnishing Machines,Deep Hole Honing Machine,Deep hole drilling Technology,Deep hole drilling accesoiries,Tube Bar,Overview Tube Bar Machines,Semi automatic 2D NC tube bending machines,Automatic Servo driven Single layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines + Roll bending,Automatic Servo driven clockwise and counterclockwise CNC Tube Bending Machines,Automatic Servo driven Left and right head CNC Tube Bending Machines,Carbide Rod Cutter - carbide Blank cutter,Wire,Overview Wire Bending - Forming,Wire Forming Machines,Spiral Forming Machines,Wire Bending Machines,Plate Sheet,Overview Plate and sheet machinery

Tel: +86-(0)571-5690 6181

Fax: +86-(0)571-5690 6183

E-mail: info@techmax-machine.com

Add: No.702, Guali commercial center, Xiaoshan district, Hangzhou, Zhejiang, China.

.jpg)