Delivery time: 60~75 days (approx.)

Payment term: T/T with 30% down payment

Warranty period: 14 months after delivery

Like it ? Share it:

- Product Details

- Technical Specs

- Standard Equipment

- Optional Equipment

- Purchase history

- Customer Reviews

- Buyers Q & A

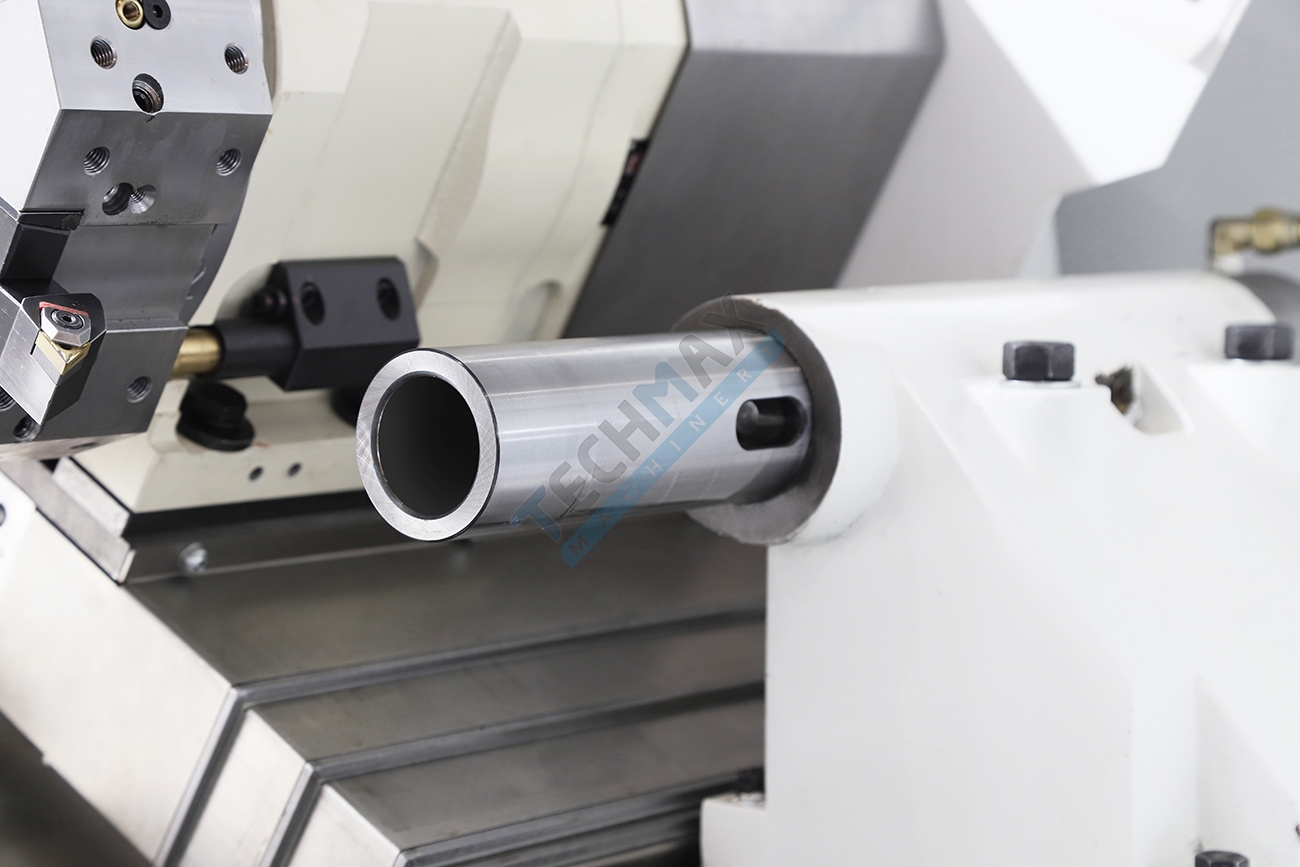

Slant Bed CNC Lathe ![]()

Model: KT-25A CNC

Center distance: 400 mm

Swing over bed: Φ500 mm

Spindle speed: 100-5000 rpm

Spindle bore: Φ63 mm

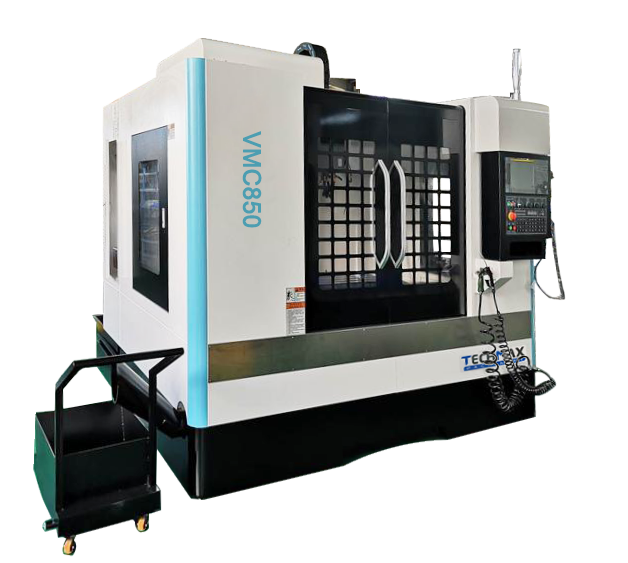

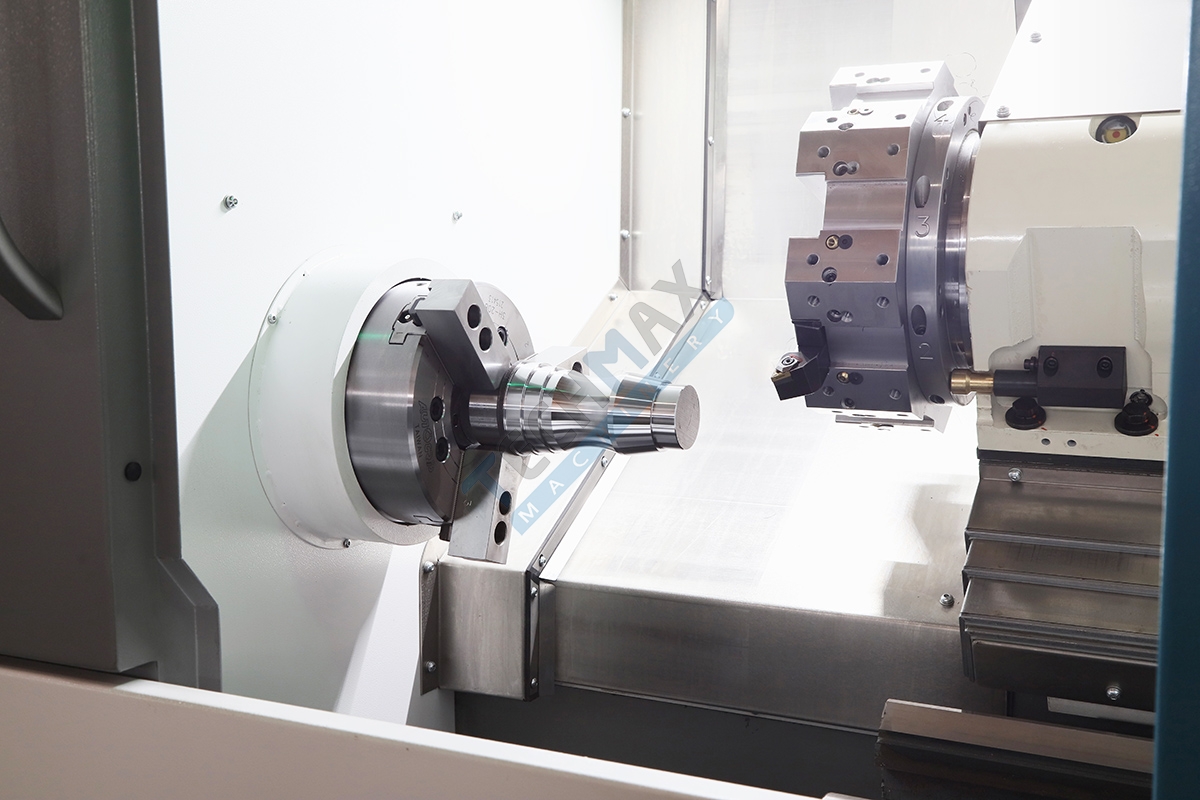

Techmax KT-series Slant Bed CNC Lathe - Description Techmax KT-series CNC lathe is designed to provide stable performance and high profit. Free to choose single workpiece processing or working with bar feeder to do machining automatically and continuously | |

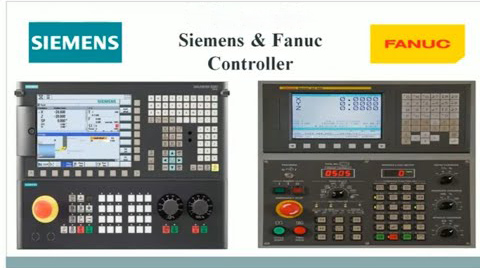

CNC System FANUC, SIEMENS, FAGOR, MITSUBISHI, GSK cnc controllers are available according to personal habits.

|

|

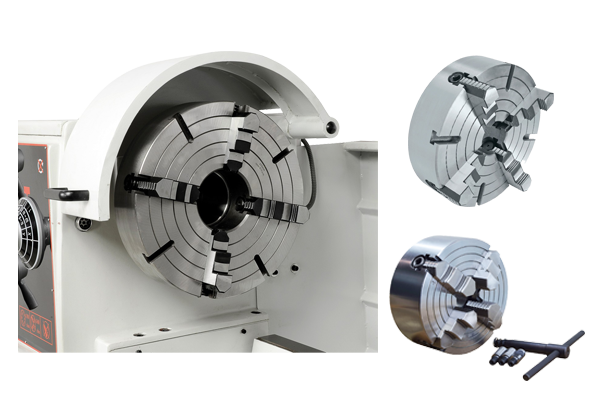

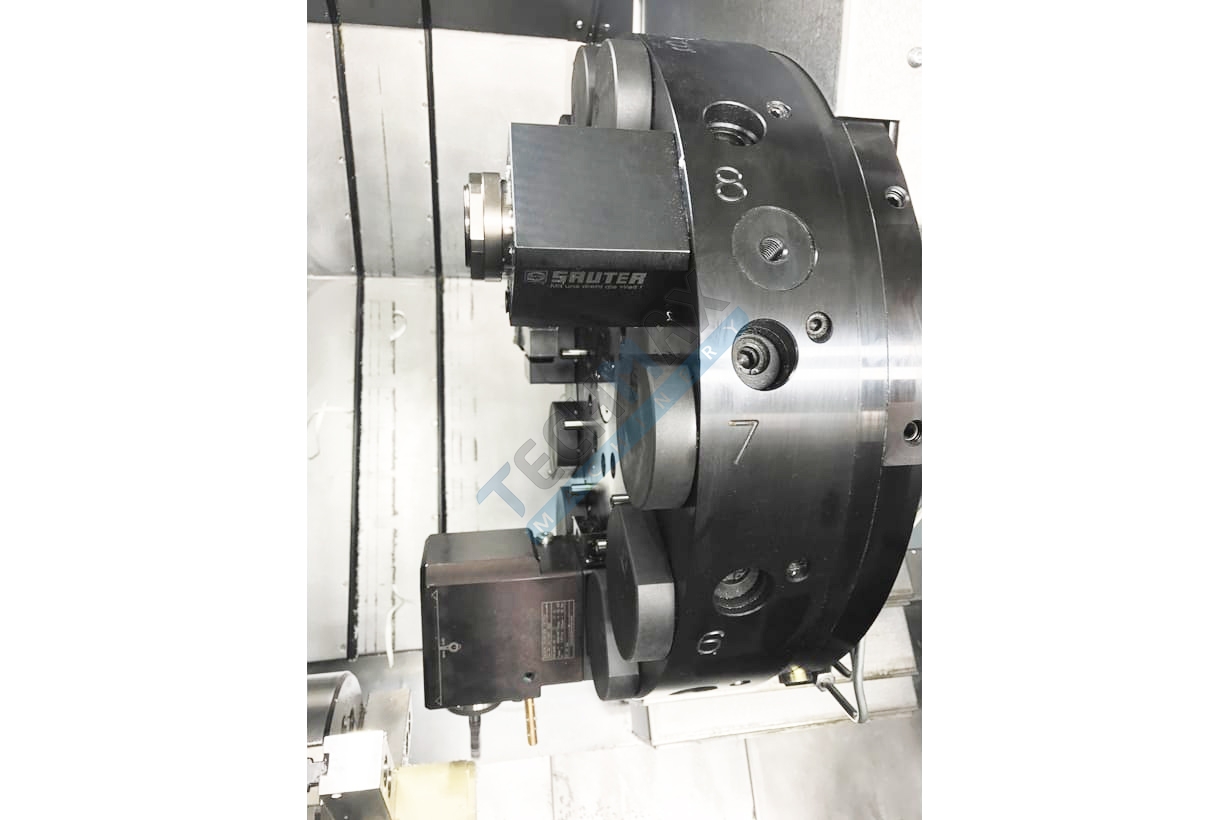

| Hydraulic Chuck This 3-Jaw hydraulic chuck provides excellent workholding capacity. It features industry-standard serrated jaws, and including all necessary adapters and tooling required for installation and operation.

|

|

|

| Hydraulic Tailstock (Option) Hydraulic tailstock or programmable tailstock (option) is available. The tailstock is an essential part of your turning operations as soon as the length to diameter ratio of your work piece exceeds 3:1. |

|

|

| Precision Ball Screws Taiwan C3 grade precision ball screws, reduced variation of motion error helps improve quality of machined surface of machine tools and productivity of semiconductor manufacturing devices.

|

|

|

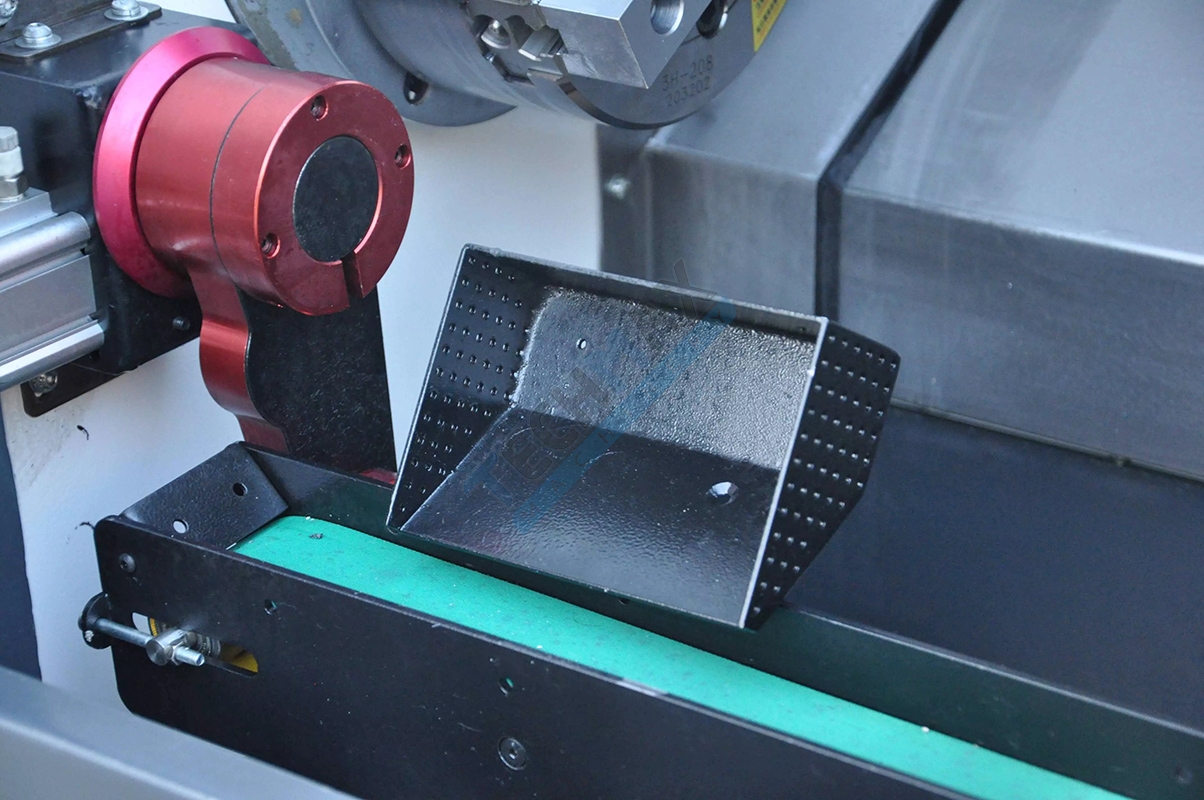

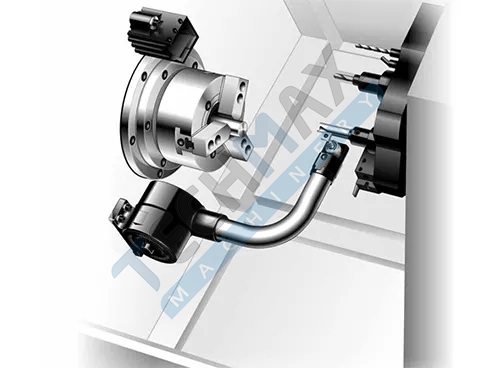

| Auto Bar Feeder (Option) Free to choose single workpiece processing or working with auto bar feeder to do machining automatically and continuously. Convenient parameters setting without need of any program modification. Length of remnant can be set as desired. Self detection for abnormal motions and is displayed on LCD.

|

|

|

| Renishaw Tool Pre-setter (Option) The Automatic Tool Pre-setter increases part accuracy and setup consistency. The system features the following: Ø Automatic, manual, and tool-breakage-detection operations Ø Conversational-style templates for easy tool-setting operations Ø No macro programming required for operation Ø Outputs G-code to MDI, where it may be edited, or transferred into a program Ø Includes User-Definable Macros option |

Model | KT-25 CNC | KT-25A CNC | KT-25H CNC |

CAPACITY: | |||

Swing over bed | Φ500 mm | Φ500 mm | Φ500 mm |

Max. cutting dia. for disc parts | Φ300 mm | Φ300 mm | Φ280 mm |

Max. cutting dia. for axle parts | Φ250 mm | Φ250 mm | Φ250 mm |

Max. turning length | 420 mm | 400 mm | 400 mm |

Hydraulic chuck dia. | 8" (200 mm) | 8" (200 mm) | 8" (200 mm) |

TRAVEL: | |||

Cross slide travel (X-axis) | 180 mm | 180 mm | 180 mm |

Longitudinal travel (Z-axis) | 500 mm | 500 mm | 500 mm |

X/Z-axis guide rails | rolling/35.45 type/mm | rolling/35.45 type/mm | rolling/35.45 type/mm |

Bed structure | 30° | 30° | 30° |

X/Z-axis ball screw dia. × thread pitch. accuracy class | Φ32×5/Φ40×10. 3 mm | Φ32×5/Φ40×10. 3 mm | Φ32×5/Φ40×10. 3 mm |

SPINDLE: | |||

Spindle speed | 3000 rpm | 100-5000 rpm | 4500 rpm |

Spindle taper | А2-6 | А2-6 | А2-6 |

Spindle bore | Φ63 mm | Φ63 mm | Φ63 mm |

Hole diameter (Hydraulic chuck) | Φ52 mm | Φ52 mm | Φ52 mm |

Max. bar diameter (hydraulic chuck) | Φ48 mm | Φ44 mm | Φ48 mm |

TOOL: | |||

Tool station number | 8 pcs | 8 pcs | 12 (driven) pcs |

Tool section size | 25×25 mm | 25×25 mm | 20×20 mm |

Max. tool diameter | Φ40 mm | Φ40 mm | Φ32 mm |

Live tool speed | rpm | rpm | 5000 rpm |

Live tool power | kw | kw | 2.2/3.7 kw |

TAIL STOCK: | |||

Tailstock quill taper | МK-4 | МK-4 | МK-4 |

Tailstock quill diameter | Φ63 mm | Φ63 mm | Φ63 mm |

Tailstock quill travel | 115 mm | 110 mm | 115 mm |

ACCURACY: | |||

Positioning accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm |

Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm |

SPEED: | |||

X/Z-axis rapid traverse | 12/20 m/min | 12/20 m/min | 10/20 m/min |

COOLANT: | |||

Coolant tank capacity | 150 L | 150 L | 150 L |

Coolant pump power | 0.55 kw | 0.55 kw | 0.55 kw |

Grease tank capacity | 1.8 L | 1.8 L | 1.8 L |

Hydraulic station power | 1.5 kw | 1.5 kw | 1.5 kw |

POWER: | |||

Main motor power | 7. 12 kw | 7. 12 kw | 7. 12 kw |

Main motor torque | 115 N.m | 115 N.m | 45; 115 N.m |

DIMENSIONS: | |||

Overall dimensions (L×W×H) | 3200×1650×1680 mm | 3200×1650×1680 mm | 3200×1650×1680 mm |

Weight approx. | 3400 kg | 3400 kg | 3400 kg |

* Specifications subject to change without notice.

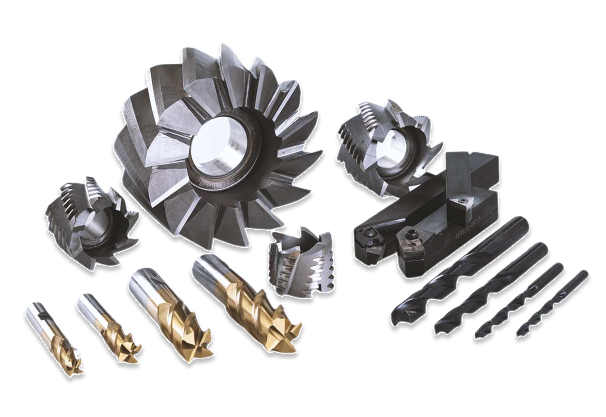

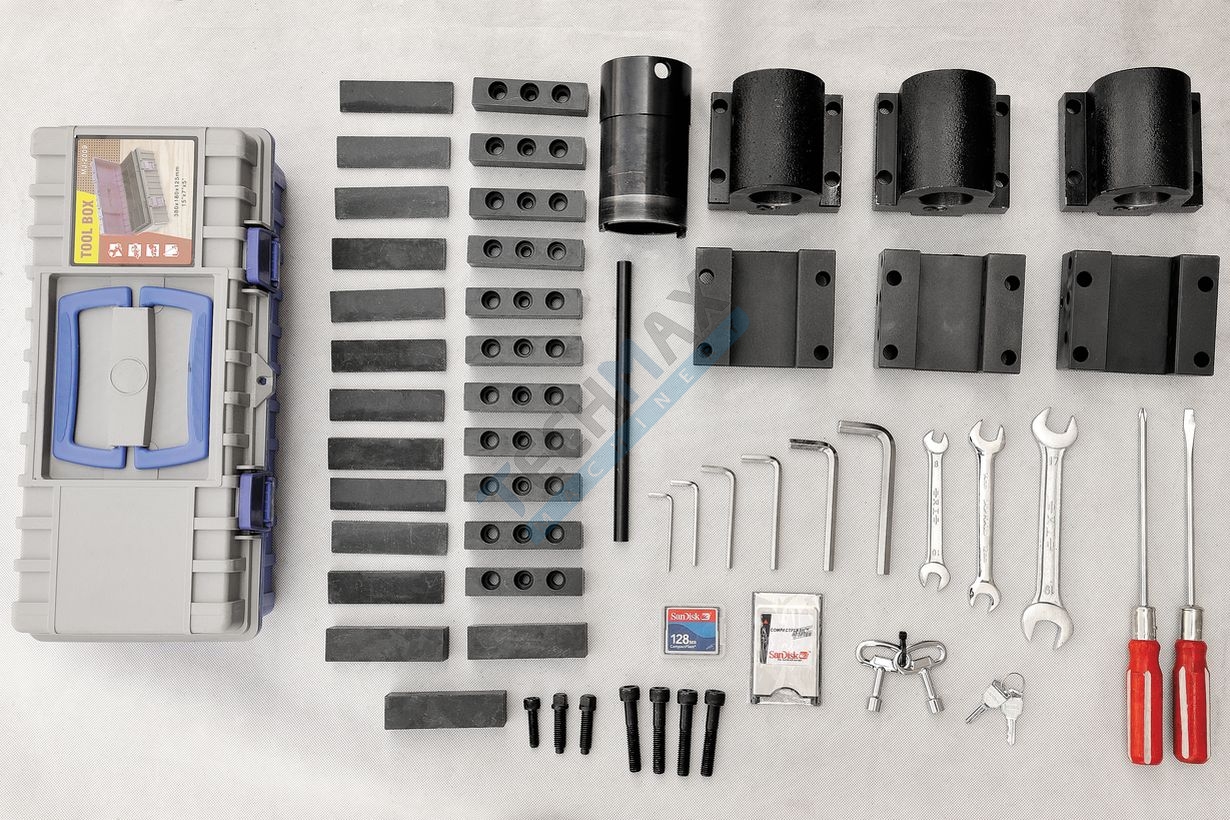

Techmax KT-series CNC Lathe - Standard Accessories | |

Complete with:

|

|

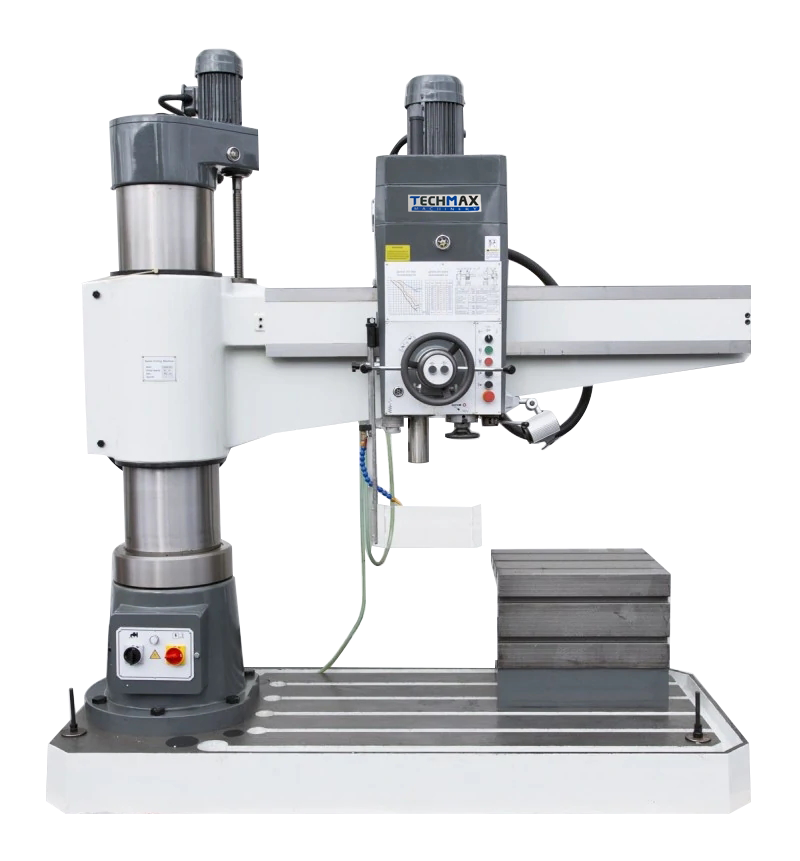

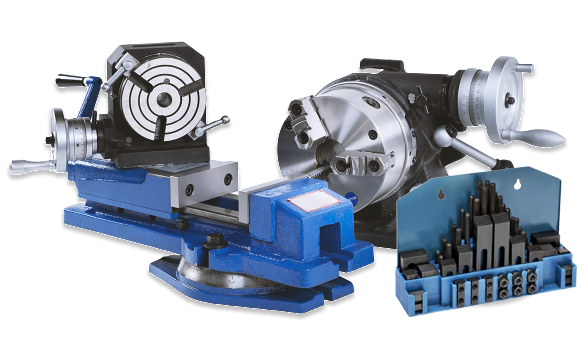

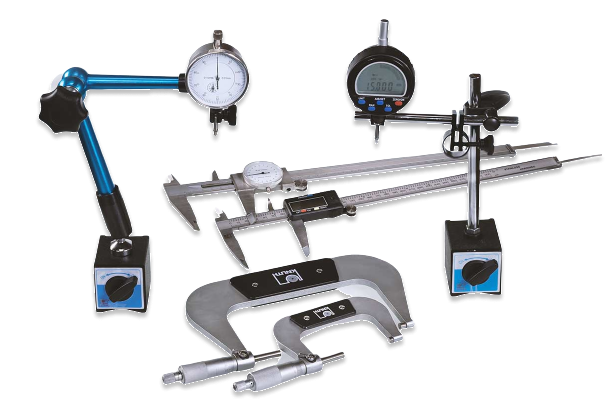

Techmax KT-series CNC Lathe - Optional Accessories | |

|

|

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Overview Grinding, Surface Grinding, Manual Surface Grinding Machine, FSG AHD Series - Automatic Precision Surface Grinding Machine (3-Axes Automatic),FSG AHR Series - Semi-Auto Precision Surface Grinding Machine (2-Axes Automatic),Cylindrical Grinding, OD Cylindrical grinding machine,Universal OD-ID cylindrical grinder, Crankshaft grinder, Centerless Grinding,Centerhole Grinding - Centre Grinding Machines,Centerhole grinding machine - Centre grinder,Centerhole CNC Grinding Machine - CNC Centre grinder,Tool grinding and Form Grinding,Five-Axis CNC tool grinder,Turn,Overview Turning,Mill,Overview Milling Machines - Machining Centers,Vertical Machining Centers - VMC Series Premium Line,High Speed Vertical Machining Centers,High Speed Graphite Milling Machining Centers,Gantry type Vertical Machining centers,Conventional Milling Machines,Drill, overview, CNC Plate drilling machine,CNC Drilling lines,optional equipment for our cnc Drilling lines, deep hole drilling machines,Hone,Overview Honing Machines,Horizontal precision Digital Honing Machines,Deep Hole Honing Machine,Vertical Deep Hole Honing Machine,Deep hole,Overview Deep hole machining,Single coordinate single spindle CNC Gundrilling Machines,Single coordinate multi spindle CNC Gun drilling Machines,Three coordinate single spindle deep hole driling machine,Deep Hole Drilling and Boring Machine - BTA Boring and drilling machines, Big diameter Boring machine - Big diameter BTA machine,Skiving & Roller Burnishing Machines,Deep Hole Honing Machine,Deep hole drilling Technology,Deep hole drilling accesoiries,Tube Bar,Overview Tube Bar Machines,Semi automatic 2D NC tube bending machines,Automatic Servo driven Single layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines,Automatic Servo driven Multi layer CNC Tube Bending Machines + Roll bending,Automatic Servo driven clockwise and counterclockwise CNC Tube Bending Machines,Automatic Servo driven Left and right head CNC Tube Bending Machines,Carbide Rod Cutter - carbide Blank cutter,Wire,Overview Wire Bending - Forming,Wire Forming Machines,Spiral Forming Machines,Wire Bending Machines,Plate Sheet,Overview Plate and sheet machinery

Tel: +86-(0)571-5690 6181

Fax: +86-(0)571-5690 6183

E-mail: info@techmax-machine.com

Add: No.702, Guali commercial center, Xiaoshan district, Hangzhou, Zhejiang, China.